PRODUCTIVITY

Our solutions improve team efficiency and reduce human errors through process automation.

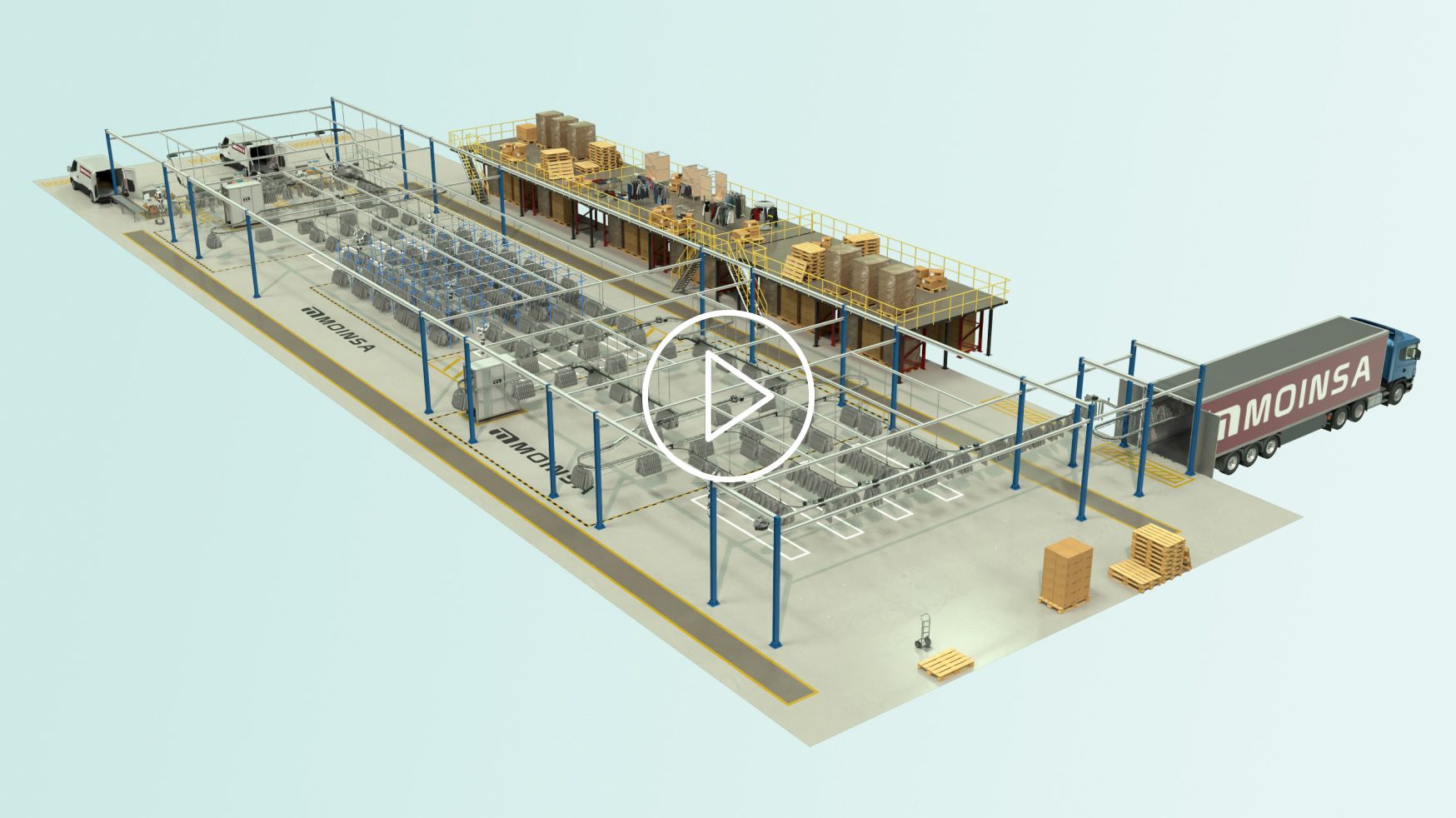

Boost sales, productivity and operational efficiency for your business

At Moinsa, we provide the expertise and solutions to enhance your business’s efficiency, competitiveness, and profitability.

PRODUCTIVITY

Our solutions improve team efficiency and reduce human errors through process automation.

EFFICIENCY

We optimize your logistics center's space and processes, reducing costs, boosting productivity, and expanding capacity.

SCALABILITY

Highly adaptable solutions meet changing market demands, ensuring long-term usability and maximized value.

As specialists in logistics consultancy, we deliver personalized services to enhance supply chain efficiency, reduce costs, and drive your company’s growth.

Get in touch with the Moinsa team for any questions you may have about our solution.

We will be happy to assist you and provide all the information you need with the utmost transparency and prompt communication.