Specialized Warehouse Management Consultancy

Our approach as specialized consultants is focused on understanding and improving every aspect of warehouse management.

We comprehensively evaluate your current operations, identifying opportunities to maximize operational efficiency, optimize resource use, and reduce costs

With over 55 years of experience, our team of experts works closely with you to design and implement customized solutions that turn your warehouse into a strategic engine of your business. From improving material flows to refining inventory control, our goal is to ensure that every process within your facilities is efficient, dynamic, and aligned with your business goals.

Your warehouse can be more than storage space: it can become a competitive advantage that drives your company’s success.

Transform your textile warehouse with our consultancy service

We turn your warehouse into a hub of efficiency and profitability. Our consulting service for the textile sector combines analysis, design and simulation so you can make strategic decisions with full confidence.

The service includes three key phases:

We thoroughly analyze the real behavior of your warehouse so you make decisions based on data, not intuition:

- We start with the real data from your Warehouse Management System (WMS) to analyze every movement in your warehouse: inbound, outbound, value-added processes, and storage.

- This analysis allows us to detect inefficiencies and opportunities with exceptional detail, offering a precise baseline.

We create an optimized layout plan for your warehouse presenting different alternatives, from full automation to improvements aligned with minimal investment.

We consider three scenarios adapted to your strategy and resources:

- Full automation to achieve the greatest efficiency and cost reduction.

- A balance between investment and automation, with a noticeable impact on results.

- Minimal and low-cost changes that still deliver visible operational improvements.

We calculate investment, savings, and return to ensure each project becomes a strategic and sustainable decision.

- Each scenario includes a clear estimate of the necessary investment and savings in operational expense (OPEX), with special emphasis on optimizing human resources.

- You will get a comparative and practical view of the return on investment you can expect from each option.

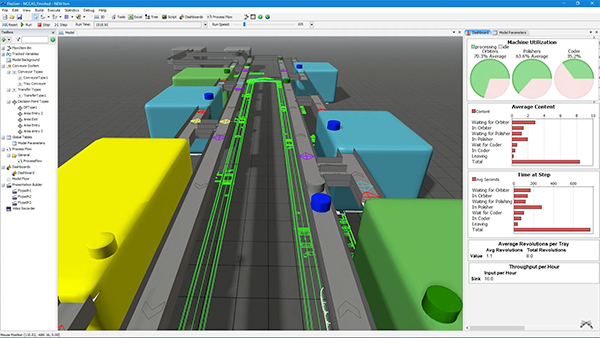

Visualize your warehouse before investing

With our FlexSim simulation, we create a virtual and dynamic model of your logistical operations that will allow:

- Real-time analysis of inbound and outbound flows.

- Detecting bottlenecks before they occur.

- Validating layout and sizing decisions.

- Measuring the impact of changes in resources, processes or demand peaks.

All simulation is based on real data from your warehouse and on the proposals defined during our consultancy.

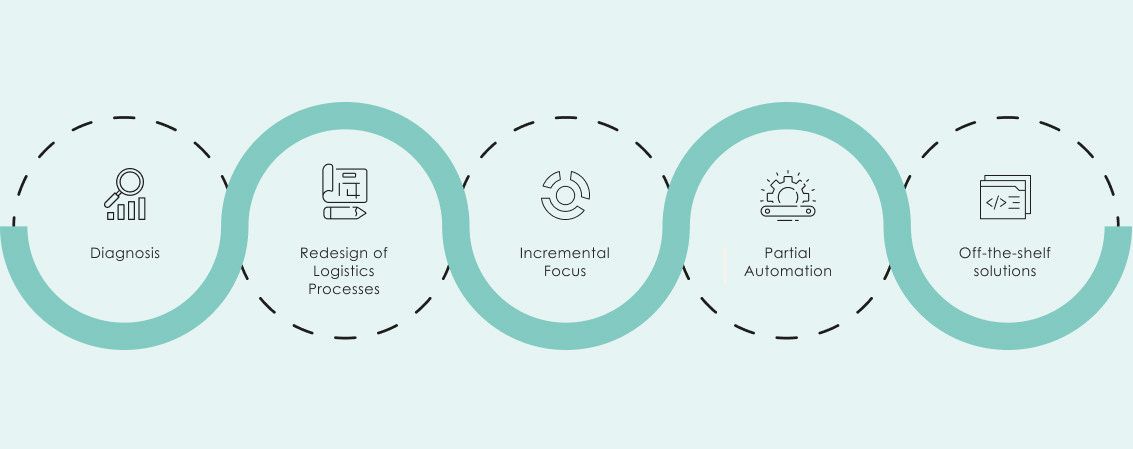

The Moinsa Method

Our methodology is designed to maximize impact in the shortest possible time. Through a five-phase approach, we ensure outstanding results.

1. Diagnosis

After analyzing data extracted from your WMS, we will compare with you which aspects of operations are open to improvement.

2. Redesign of logistical processes

If the prior diagnosis and your team agree, we will prioritize those logistical flows whose improvement is both most significant and requires the least investment.

3. Incremental approach

Whether through technological improvements or redesigning operations, we aim to consolidate an initial improvement in warehouse operations. Each improvement must be stabilized before moving on to the next.

4. Partial automation

When automation is the improvement path being explored, it will be proposed only for items with highest turnover. We will implement scalable solutions with a contained initial investment.

.

5. Off-the-shelf solutions

We always prioritize technology that is available and proven in the market. The modularity of any solution allows:

- Integration with other devices or technologies.

- Scalability: any modular solution is designed to grow.

- Cost-effectiveness: custom development always entails higher cost.

Advantages of working with Moinsa

Your success is our objective

To achieve success, you must choose well which partners you count on to reach it. Success does not happen overnight: consistency is key and precisely that long-term commitment is the value we bring to our clients.

We have the trust of companies in diverse sectors

Our clients are our best endorsement. We have over 55 years of experience in logistics consultancy, working with companies of various sectors and sizes. Chances are you know someone who has worked with Moinsa!

What is not measured, cannot be improved

Our work begins with the analysis of available data and, if there is no data (in digital form), we provide the means to obtain it. Then, we present the diagnosis based on your own data.

Differential approach

At Moinsa, we do not speak of Blockchain, Big Data or exponential Generative AI. We have a different focus:

- Off-the-shelf and scalable solutions.

- Consolidation of the first improvement before addressing the second.

- Focus on what matters most.

Increase your profitability starting now

Get in touch with the Moinsa team for any questions you may have about our solution.

We will be happy to assist you and provide all the information you need with the utmost transparency and prompt communication.